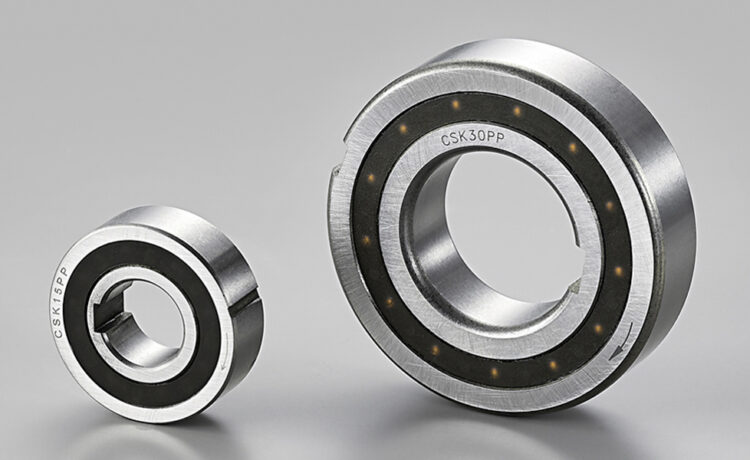

Precision and durability are important factors in performance and inefficiency in the industry of machinery and electronics. Smooth operations and heavy load support as well as reducing friction rely on the use of bearings. Among all bearing choices, NR Bearing (ตลับลูกปืน lm guide nr, which is the term in Thai) is excellent because of its design and durability. These bearings are used whether in industrial equipment or high-speed applications and offer stability and long service. This article explores the benefits and applications of NR bearings in the modern machinery industry.

Key Features of NR Bearings

NR bearings are specially made for use in machinery and are equipped with feature-rich qualities that make them highly reliable. These include:

1. High Compression and Vibration Resistance

Resistance against compression and vibration is one of the strongest features of NR bearings. Due to their strength, they are perfect for heavy-duty machinery necessary for high operational stress. It allows the bearing and the machinery to last as long as possible.

2. High-Speed Performance with Precision

The NR Bearing design is to operate at high speeds with the precision to be uncompromising. This feature is most important in automated manufacturing and high-speed production lines, where accuracy is critical. This cage type can reduce misalignment, achieve stability and help reduce vibration.

3. Enhanced Durability

In the selection of bearings for use in industry, durability is an important factor. NR Bearings are created with high-quality materials for long-term performance. Their construction is robust enough to carry high amounts of loads without overwear and tear, which makes them a cheap option for businesses.

4. High Load Capacity

Machinery used in heavy industries requires bearings that can support substantial loads. Designed with a limit in mind, these NR bearings are capable of dealing with major weights and pressure, making them a good fit for construction equipment, manufacturing plants and high-load machinery systems.

Applications of NR Bearings in Machinery

The range of possible applications for NR Bearings extends from basic usage to multiple advanced applications because of their versatility.

- Heavy Machinery: NR Bearings belong to heavy machinery applications because they operate inside construction equipment and mining equipment within harsh environments.

- Automotive Industry: Industrial vehicles and production machinery use NR Bearings because they deliver dependable and smooth motion control in high-end systems.

- Electronics Manufacturing: The electronics manufacturing industry requires these components to function in fast-operating automated assembly processes that need both precision and speed performance levels.

Conclusion

The machinery industry strongly depends on NR Bearings because they unite superior strength with exact positioning features alongside substantial load limits. The combined function of high-speed operation with vibration resistance properties and heavy load capabilities makes them optimal for industrial application performance. The purchase of premium NR Bearings extends operational lifetime while enhancing productivity, which produces lasting commercial advantages for organizations.